In order to 3D Print, you will need 3D print filaments to use with your printer that actually creates the object you are building. The two main categories of 3D Printers are: Resin (also known as SLA) and FFF.

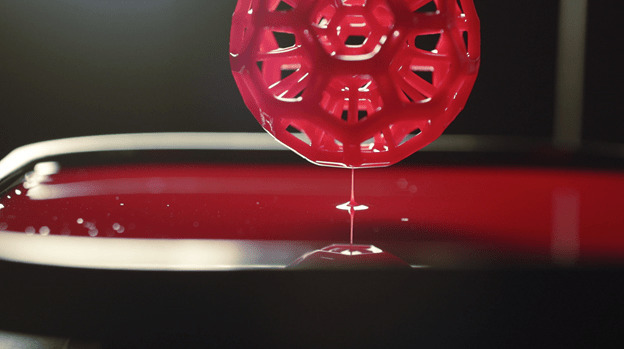

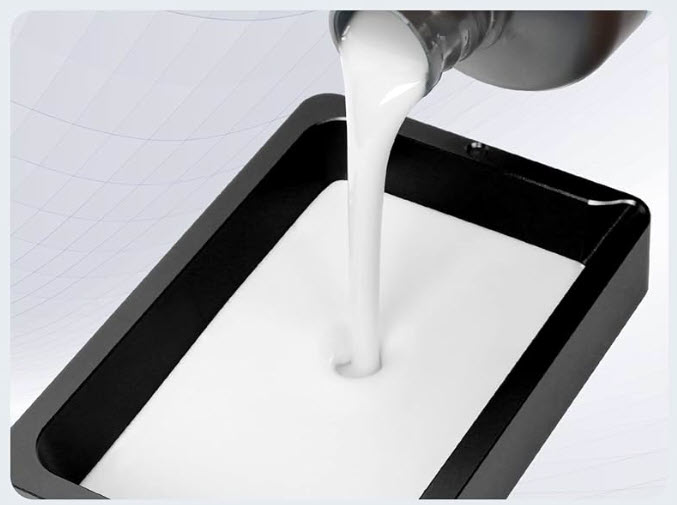

For a Resin printer, you fill up your 3D printer with a resin liquid. A laser heats up the liquid to form whatever object you have programmed into it. You’ll need to have enough resin to complete your build as well as isopropanol alcohol to clean the 3D printed item when it’s complete.

FFF 3D Printers use filaments that are melted and shaped, built layer by layer. There are a variety of filaments that you can choose which have different strengths. You should decide what type of filament to use depending on the object you are creating and its purpose.

Resin/SLA

Resin is the fuel that keeps your 3D Printer working. If you run out of resin, you will not be able to continue building. When you buy a Resin 3D printer, you should receive enough resin to at least get you started. You can always buy extra when you start to get the hang of it.

Many slicer programs will give you an estimate on how much resin you will need to complete the build. This is an estimate and you will need to use more than the program calls for. You can always remove any excess resin and place it back into the bottle.

You can buy resin for a variety of purposes. If you are a beginner to Resin 3D Printing, you will likely want to use Standard Resin. You can also buy resin made for Jewelry (sometimes referred to as ABS), Heat Resistant or Flexible Printer Resin. Resin is available to purchase online. I haven’t had any luck in my area finding Resin in the store. It would be in the craft section if your store carries it. It is available in sizes ranging from 1kg to 500G.

Before you print, make sure the resin is not too cold. The ideal temperature for Resin is between between 24°C-30°C. Avoid printing if your resin is less than 18°C. You should heat up the resin before using it by raising the ambient temperature of the room or installing a heater for your printer.

FFF Filament Types

FFF 3D print filaments come in a variety of colors, strengths and sizes. Think of filaments like the ink of your 3D printer. The standard size of FFF Filament is 1.75mm. The two most common filament types are PLA and ABS. They are made of plastic material that when heated doesn’t burn but becomes shapeable. I have included the term name for filaments where they apply, but most of the time, you will just see the abbreviations. This is the most common way you will see it listed on other websites and it makes it easier to read.

The main difference between the different types of filaments is the temperature it takes to melt and the strength of the material after it’s created. Let’s take a look at some different filaments you’ll want to consider when using your 3d Printer.

PLA (Polylactic Acid)

One of the most common types of filaments being used today by hobbyists and 3D home printers. It’s less expensive than a lot of the other filaments on this list. It’s easier to use as it tends to clog less and allow more details to come through on your finished build. It also comes in a variety of colors and is biodegradable. PLA has a lower heat level compared to the other filaments listed here. If you are just starting out in 3D printing, PLA is a great option for beginners. I would recommend taking some time to get experience cranking out projects with PLA filaments. After that, you can try out some of the other filament options.

- Nozzle Temp: 180°C-220°C

- Bed Temp: 20°C-60°C (Use if Heated Bed is Available)

ABS (Acrylonitrile Butadiene Styrene)

This is a tougher material to work with. It will bring stability to your finished build. Think about the material that Lego is made out of. In order to heat this filament properly, you will need to invest in a heated bed. You will also need to use your 3d Printer in a well-ventilated area as this material will vent fumes when it’s been heated. If you are building something that you want to make sure it’s strong, like a shelf, hook or support, this may be a good direction to go. It is also heat resistant and is a great option for items you plan on using outdoors.

- Nozzle Temp: 210°C-250°C

- Bed Temp: 90°C-110°C (Heated Bed Required)

ASA (Acrylonitrile Styrene Acrylate)

ASA is a tougher version of ABS, about 10 times more weather resistant which makes it ideal for use outdoors. This type of filament will help your printed object to last much longer but it will be more expensive to buy that ABS. You will be able to use ASA in most 3d Printers so that is a plus.

- Nozzle Temp: 240°C-260°C

- Bed Temp: 90°C-120°C (Heated Bed Required)

PETG (Polyethylene Terephthalate Glycol)

This filament provides a good balance between strength and ease of use. It’s transparent and resistant to chemicals. PETG filaments can be used to create food-safe containers, plates, cups and mugs.

- Nozzle Temp: 220°C-250°C

- Bed Temp: 50°C-80°C (Glue or Heated Bed)

TPU (Thermoplastic Polyurethane)

The most flexible filament on the list produces rubber like products and can handle an impact. This is a great option when you may want an item that is able to bend slightly. Think of RC Cars, Drones, phone cases or shoes as practical applications with this type of filament.

- Nozzle Temp: 210°C-230°C

- Bed Temp: 30°C-60°C (Heated Bed Required)

Nylon

It’s strong and durable while still being very flexible when it’s thinner. This material is a perfect option for moving parts such as gears or hinges. Heated bed is required for nylon 3D filaments and your printer will need to be able to achieve heat between 220°C-250°C.

- Nozzle Temp: 240°C-290°C

- Bed Temp: 55°C-65°C (Heated Bed Required)

Caring for Your Resin and Filaments

Here are some tips when working with your Resin 3D Printer.

- It is recommended to shake up your resin before pouring it into the bin of your 3D Printer.

- Keep away from direct sunlight as Resin is sensitive to UV light.

- Handle with care and always wash your hands.

- Some people are allergic to resin and make react when handling it, even if it’s dry.

- You may need to use gloves when handling a resin 3D printed object before you have cleaned it.

- You can store your resin in your printer after use or pour it back into the bottle.

- Resin will last for several months inside the printer if it’s covered and stored in a cool, dark room.

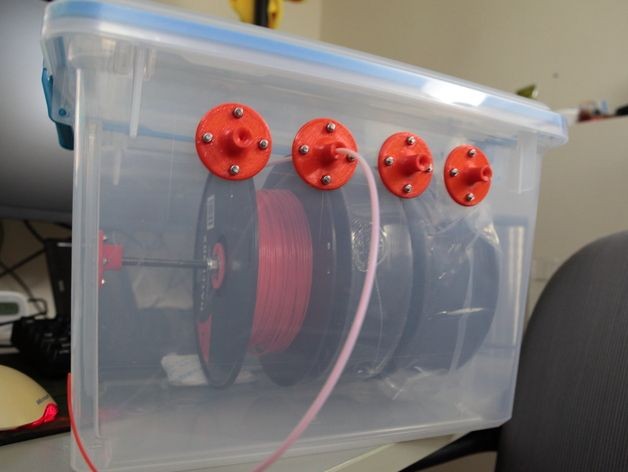

FFF 3D Print Filaments

When it comes to FFF filaments, taking care of the materials that will be used with your 3D printer is essential. Keep your filaments away from heat, light and dust. Dust can damage your 3d Printer’s nozzle.

Poorly stored filaments can cause jams, issues with layers joining together or leave gaps which will affect the quality of your finished build. Not taking care of your filaments can drastically increase print fails or even damage your 3D printer.

Keep your filaments stored at the recommended temperature range. Filaments can attract moisture which will make them more likely to be brittle and snap during printing. Nylon filaments are even more likely to absorb moisture compared to the other FFF filament types. Store your filaments in an air type container, vacuum bag or a storage container designed for filaments to reduce the risk of moisture in your filaments.

If you hear a popping sound while printing, this could be a sign that your filament has absorbed too much moisture and needs to be dried.

How to dry your 3D print filaments

If your FFF filaments has already been exposed to too much moisture, you’ll want to dry it out before using it. You can use a filament dryer which is specifically designed to keep filaments dry and remove moisture. You could also try a food dehydrator. You’ll have to make some adjustments to the spool to get it to fit. Another option would be to use your oven but temperatures can vary so it won’t be exact. If you use too high a temperature, you risk melting the spool. If you dry out your filaments too much, you risk the potential that they could start to stick together. It’s best to store them in a cool dry container to avoid moisture being allowed to accumulate.

As you began (or continue) your journey in 3D printing, the materials you buy will depend on the objects you want to 3d print and their purpose. Keeping your work area clean and taking care of your filaments will help you to produce quality prints.

So What’s Next For My 3D Print Journey

Everyone is at a different place when it comes to 3D printing. Follow our links below to learn more and remember to do your best to avoid getting to Step 7.

- Step 1: Interest in 3D Printing

- Step 2: Buy Equipment

- Step 3: Print Other People’s Designs

- Step 4: Print Your Own Designs

- Step 5: Upgrade Printer

- Step 6: Sell Products

- Step 7: Quit 3D Printing